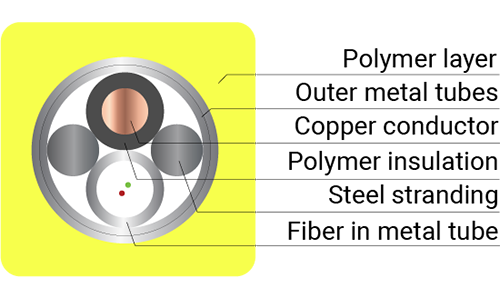

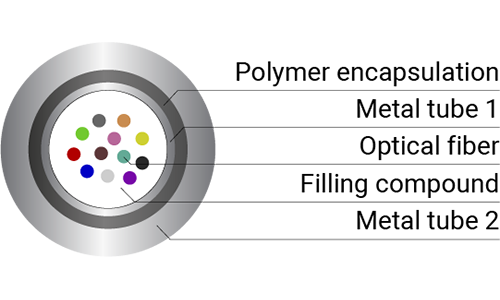

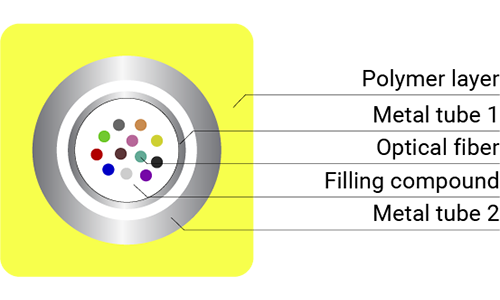

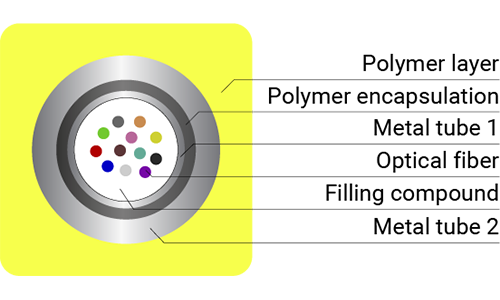

Our robust, compact monitoring cables combine copper conductors and optical fibers to provide flexible, customer-specific solutions for distributed sensing, high-speed telemetry, and power delivery. Designed for demanding oil and gas environments, they withstand extreme pressures, temperatures, mechanical stresses, and harsh fluids, enabling reliable, real-time monitoring and intervention. Fiber and material combinations can be customized to meet specific operational requirements, ensuring precise data acquisition and consistent performance over the life of the well.

Our products for permanent cables are manufactured to customer specifications.

Below are just a few examples to demonstrate our production capabilities.

+ 90 °C

+ 125 °C

+ 140 °C

+ 200 °C

+ 194 °F

+ 257 °F

+ 284 °F

+ 392 °F

Maximum Rated Design Tension

900 – 2250 lbf

Crush Resistance

1 kN / cm

4.5 – 12.7 mm

0.157 – 0.472

Minimum bending radius

x 20D

x 20D

Well Intervention involves various techniques aimed at managing and enhancing well performance. Common methods include Slickline, Coiled Tubing, and Hydraulic Workover. These techniques are used for tasks like scale removal, artificial lift, well stimulations, and addressing mechanical failures. The goal is to maximize production efficiency and extend the life of the well.

Slickline is a thin cable used for deploying tools and equipment down into an oil or gas well for various tasks, including well diagnostics, plugging, pressure and temperature measurement, and sampling. It’s essential for routine maintenance and data gathering to ensure efficient well operations.

Coiled Tubing (CT) is a continuous length of steel or composite tubing used for interventions in oil and gas wells. Unlike Slickline, which is non-rigid, Coiled Tubing can pump fluids into the well and is capable of rotary drilling actions. CT is used for more complex operations such as drilling, fracturing, and scale removal due to its ability to apply hydraulic power.

FIMTs are designed with materials specifically chosen for their corrosion resistance to environments containing hydrogen sulfide. The metal tubes, often made from stainless steel or specially alloyed materials, provide excellent protection for the optical fibers against the harsh chemical interactions found in sour environments.

Yes, we offer customization options for FIMTs to match the specific requirements of operations in sour environments. This includes selecting the most appropriate corrosion-resistant materials and designing the FIMTs to meet the particular challenges of each application.

For applications in sour environments, FIMTs typically utilize corrosion-resistant alloys such as stainless steel 316L, Alloy 825, or Alloy 625. These materials are known for their high resistance to a wide range of corrosive conditions, including those found in sour oil and gas fields.

We’re here to help! Reach out to us for any technical inquiries or assistance.