In the dynamic field of Oil & Gas, our specialized Fiber in Metal Tubes (FIMTs) are instrumental in advancing fiber optic solutions for well completions and interventions. These FIMTs provide a durable and reliable medium for high-tech fiber optic sensing, essential for real-time monitoring and data acquisition in complex operations.

Fiber optic technology provides durable and reliable real-time monitoring and data acquisition for oil and gas operations. Distributed Acoustic Sensing (DAS) enables fracture mapping and fluid movement analysis in harsh downhole conditions.

Integrating fiber optics boosts the precision and efficiency of well interventions like Slickline and Coiled Tubing. This advanced monitoring enhances tasks such as scale removal and artificial lift, leading to safer and more effective processes.

Fiber optic systems offer continuous pipeline monitoring for early leak detection and external threat identification. Distributed Fiber Optic Sensing (DFOS) pinpoints changes in temperature, noise, and vibration, crucial for maintaining pipeline integrity and environmental safety.

Fiber optics are used in downhole communication, hydraulic fracturing monitoring, and temperature sensing within the oil and gas industry. These technologies provide key insights for informed operational decisions and enhance overall efficiency through high-speed data transmission.

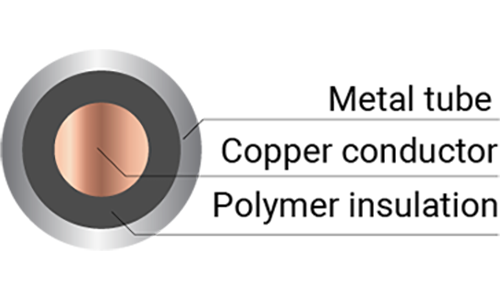

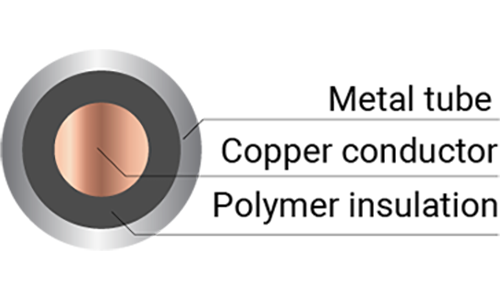

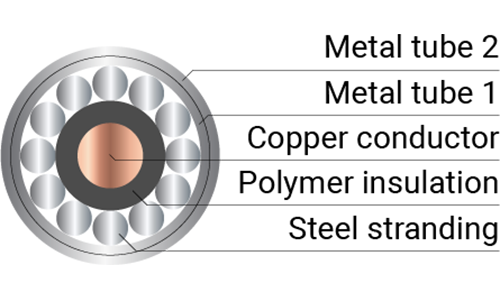

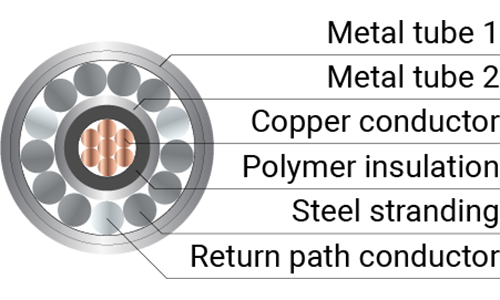

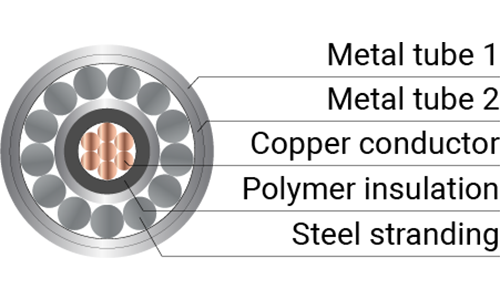

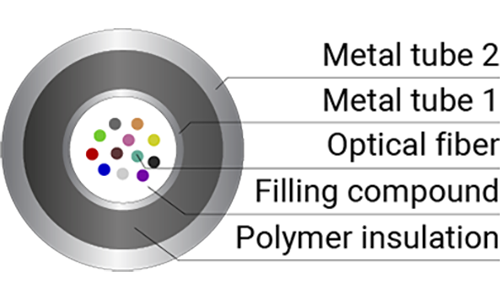

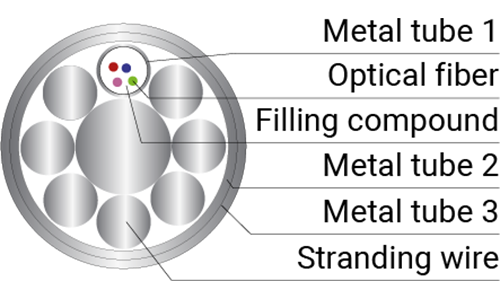

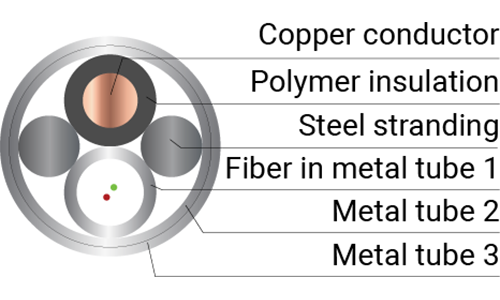

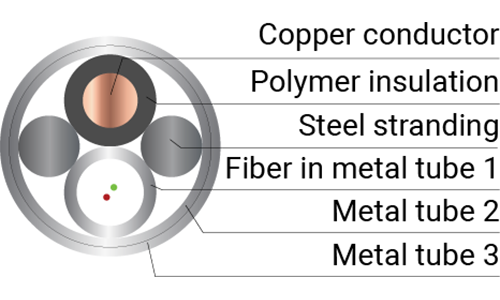

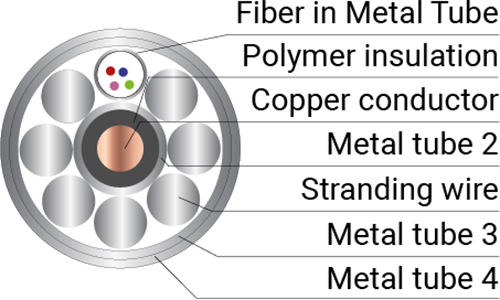

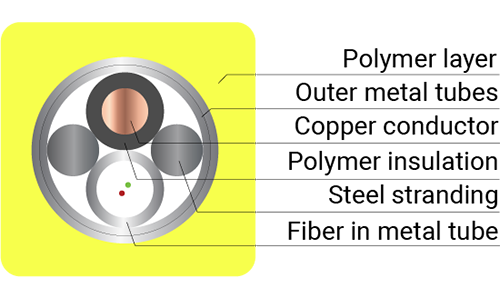

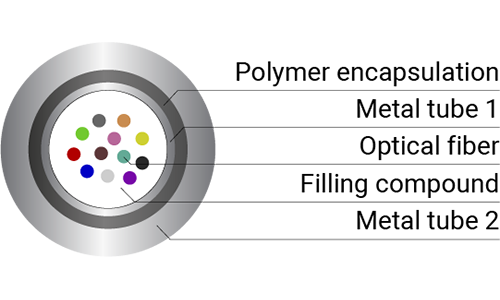

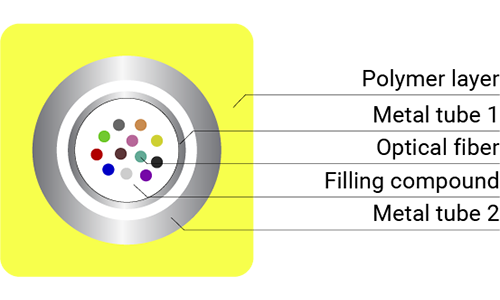

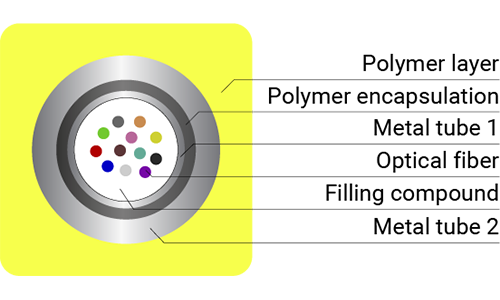

Our cables for well services are manufactured to customer specifications.

Below are just a few examples to demonstrate our production capabilities.

+ 90 °C

+ 125 °C

+ 140 °C

+ 200 °C

+ 194 °F

+ 257 °F

+ 284 °F

+ 392 °F

Maximum Rated Design Tension

900 – 2250 lbf

Crush Resistance

1 kN / cm

4.5 – 12.7 mm

0.157 – 0.472

Minimum bending radius

x 20D

x 20D

NBG’s cables for well services are typically manufactured from Inconel, enabling operation in sour environments. For non-sour environments, 316L stainless steel can be used to reduce cable costs.

Yes, we offer customization options for the cables to match the specific requirements of operations in sour environments. This includes selecting the most appropriate corrosion-resistant materials and designing the cable to meet the particular challenges of each application.

For applications in sour environments, FIMTs typically utilize corrosion-resistant alloys such as Alloy 825, or Alloy 625. These materials are known for their high resistance to a wide range of corrosive conditions, including those found in sour oil and gas fields.

We’re here to help! Reach out to us for any technical inquiries or assistance.