Integrating Fiber in Metal Tubes (FIMTs) into ropes and ropeways, such as those used in gondola lifts, represents a significant advancement in operational technology, enhancing both safety and efficiency. By incorporating FIMTs, these aerial lift systems gain crucial sensing and data transmission capabilities, enabling real-time monitoring of critical parameters like cable tension, temperature, and overall structural integrity.

This technology not only provides an additional layer of safety for passengers by ensuring timely maintenance and immediate detection of potential issues but also improves the operational management of the lift system. With FIMTs, operators can continuously monitor the health of the ropeway, optimize maintenance schedules based on actual conditions rather than predefined intervals, and significantly reduce downtime.

Moreover, the robustness of FIMTs ensures reliable performance in the challenging environmental conditions often encountered by gondola lifts, such as high wind and ice loads, temperature fluctuations, ligthning strikes, fires and precipitation, making them an ideal solution for enhancing the safety and efficiency of ropeway systems.

Our products for Ropes / Ropeways are manufactured to customer specifications.

Below are just a few examples to demonstrate our production capabilities.

Integrating FIMTs into ropes and ropeways provides advanced sensing and data transmission capabilities. Fiber optic sensing technology enables real-time monitoring of cable tension, vibrations, temperature changes, potential wear, and lightning strikes, enhancing both safety and operational efficiency.

FIMTs deliver continuous, real-time data on the condition of ropeways, enabling immediate detection of abnormalities or potential issues. Fiber optic-based distributed acoustic sensing (DAS) or FBG-based acoustic sensing can detect and localize potential lightning strikes, helping minimize downtime for lift operators.

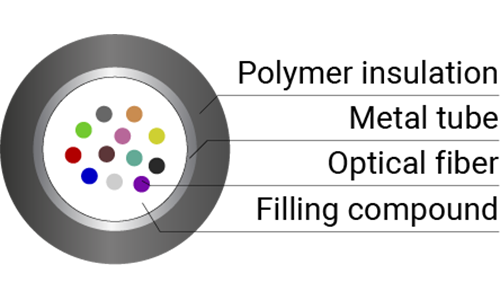

FIMTs are designed to protect optical fibers from extreme conditions, including high winds, temperature fluctuations, and moisture, common in ropeway environments. The metal tube encasing the fibers provides a durable barrier against physical damage and offers optimal protection against lightning strikes, ensuring consistent and reliable data transmission. This is essential for maintaining operational safety and efficiency in critical monitoring and control applications.

We’re here to help! Reach out to us for any technical inquiries or assistance.