Distributed Fiber Optic Sensing (DFOS) allows for fully distributed temperature sensing over multiple kilometers without the need of electricity at the measurement position. It is a key technology for monitoring critical infrastructure such as LNG pipelines and tanks, oil and gas pipelines, chemical plants, kilns and other harsh environments.

NBGs cables support Raman, Brillouin, Ralyeigh or FBG based interrogation technologies with Raman being the most common technique for cryogenic and high temp environments. The full metallic protection of the fibers ensure long lasting sensors by protecting the fibers from environmental influence and strain during operation.

Our Cryogenic FO cables are manufactured to customer specifications.

Below are just a few examples to demonstrate our production capabilities.

Our High Temp FO cables are manufactured to customer specifications.

Below are just a few examples to demonstrate our production capabilities.

Sentire T Cryo cables operate across a temperature range from +40°C down to -196°C and can be directly submerged in liquid nitrogen. Sentire T150 and T300 are designed for operation from room temperature up to 150°C and 300°C, respectively, with short-term exposure to higher temperatures also possible.

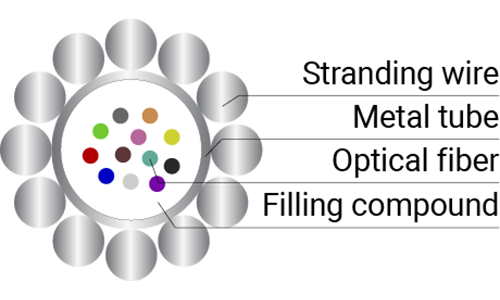

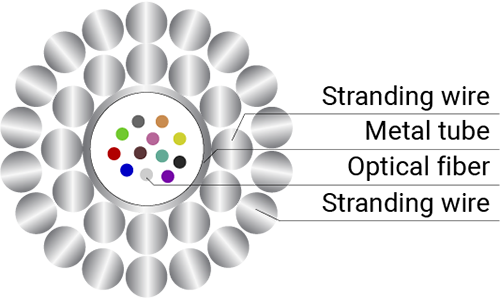

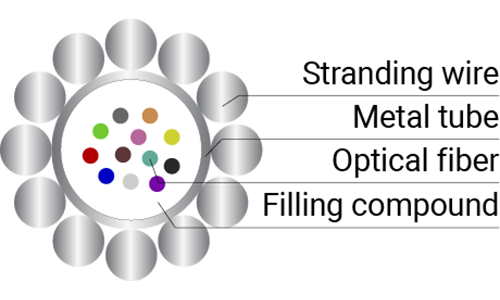

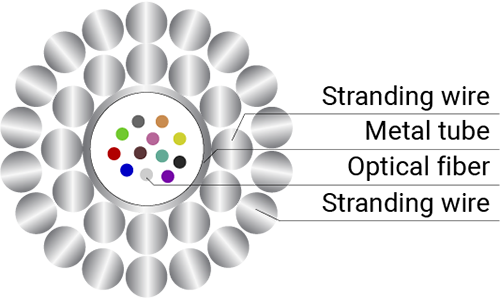

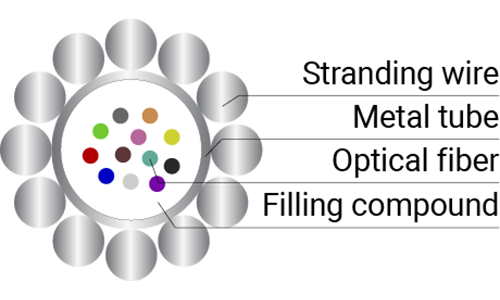

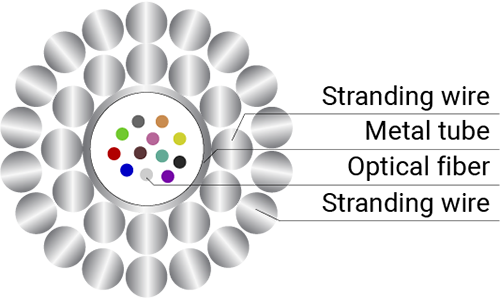

The metal tube provides optimal protection for the fibers against environmental influences, and the loose tube design ensures strain-free fibers even at operational temperature limits. Additional layers enhance crush resistance and tensile strength.

Stranding wires can be removed with pliers, while the tube can be cut using a pipe cutter or triangular file. NBG also offers a specialized tool that creates a corrugation on the tube, preventing damage to the fiber coating from burrs at the tube edge.

While the standard material for sensing cables is 1.4404 (316L), which has limited suitability for sour environments, NBG also offers nickel alloy options for these demanding applications.

Single lengths of up to 8 km are available. The final length is determined by the customer’s order and delivered on a wooden drum with both ends accessible. Fiber optic connectors can be provided upon request.

NBG offers fiber optic sensing cables with fibers compatible with ITU-T G.652.D or ITU-T G.651 standards, ensuring compatibility with the majority of interrogators.

We’re here to help! Reach out to us for any technical inquiries or assistance.