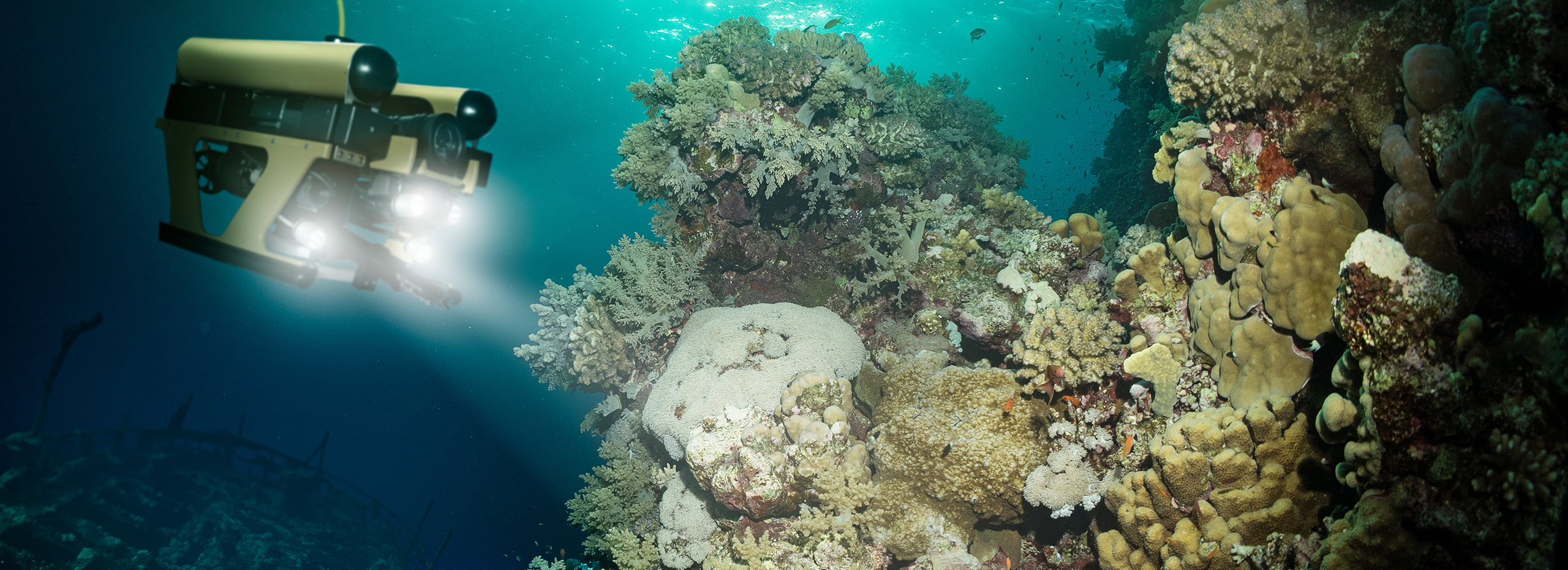

Our FIMTs are engineered to withstand the rigorous conditions of underwater use, providing both structural integrity and reliable fiber optic communication capabilities.

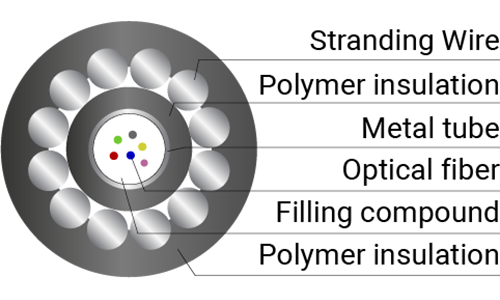

Their construction allows for high fiber density, accommodating numerous fibers in a compact space, which is essential for the multifaceted functionality of umbilical cables. With the capability to be supplied in multiple kilometers in a single lengths, they reduce the need for frequent splicing, thereby enhancing the overall efficiency and reliability of the umbilical cables.

NBG’s focus on quality manufacturing ensures that these FIMTs are not just components, but critical enablers of advanced, durable, and efficient umbilical cable systems, essential for a wide range of maritime and subsea applications.

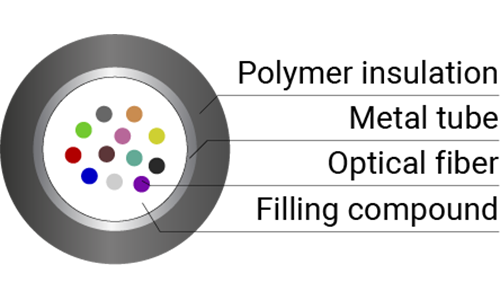

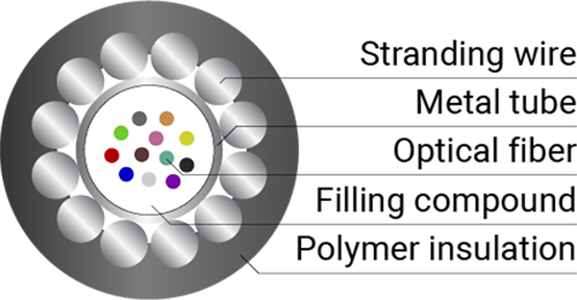

Our products for umbilical cables manufactured to customer specifications.

Below are just a few examples to demonstrate our production capabilities.

FIMTs in umbilical cables provide excellent fiber protection, high fiber density for data transmission, and are ideal for sensing applications. The metallic encapsulation’s high crush resistance and superior breaking strength allow easy integration into larger cable assemblies. These features are essential for ensuring the reliability, efficiency, and performance of umbilical cables in demanding environments.

High fiber density allows for a greater amount of data to be transmitted through a single cable, maximizing the bandwidth and efficiency of communication lines. This is particularly beneficial for umbilical cables that need to support multiple functions simultaneously, including power delivery, data transmission, and real-time monitoring.

FIMTs in umbilical cables can support a range of sensing applications, such as Distributed Temperature Sensing (DTS), Distributed Acoustic Sensing (DAS), and Distributed Strain Sensing (DSS). These applications are vital for monitoring the operational health of the umbilical system, environmental conditions, and ensuring the safety and efficiency of operations.

NBG offers FIMTs in continuous lengths of up to 50 km. These extended lengths greatly reduce the need for splicing, enabling smoother and more efficient installations while enhancing overall system integrity by minimizing potential points of failure.

Our FIMTs for umbilical cables can accommodate up to 192 fibers in a single tube. This high fiber count is advantageous for complex applications requiring substantial data transmission capabilities, such as remote operations and real-time monitoring.

NBG utilizes thixotropic gels with high hydrogen absorption capacity and high viscosity. The hydrogen absorbers prevent fiber darkening by capturing diffused hydrogen molecules, ensuring long-term signal integrity. With a filling degree exceeding 90%, the gel also provides the longitudinal water tightness required by subsea cable standards.

We’re here to help! Reach out to us for any technical inquiries or assistance.