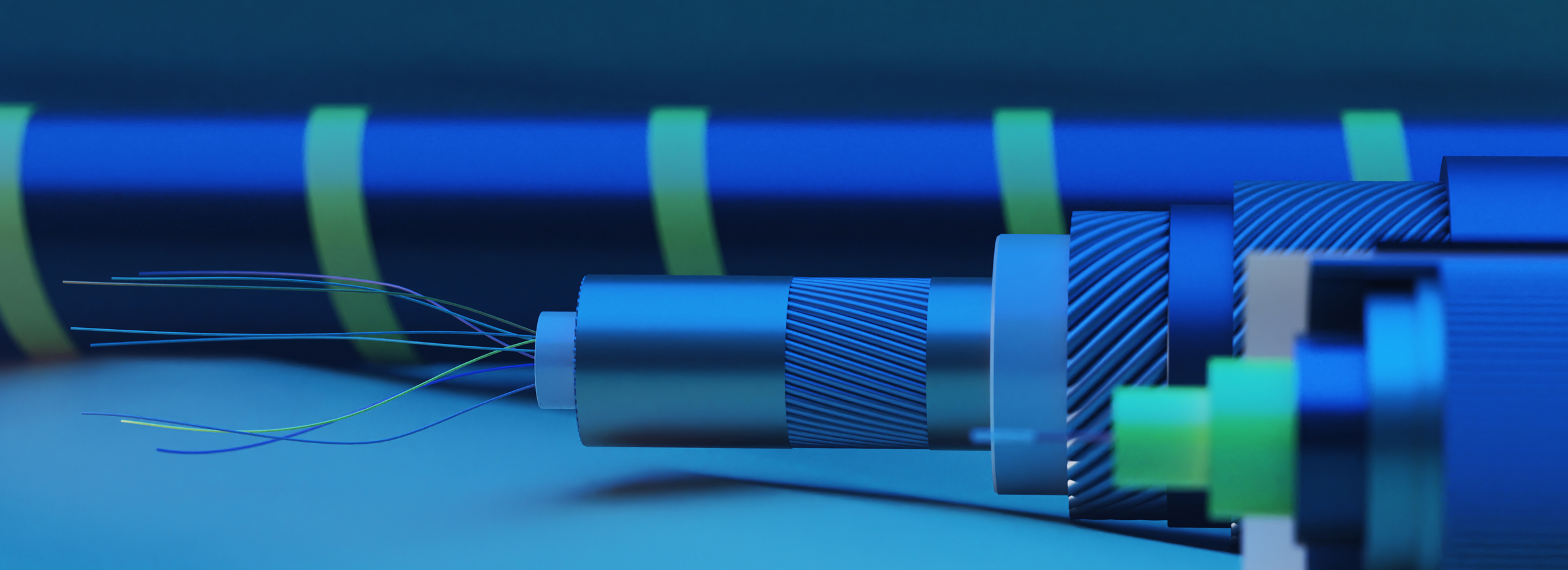

NBG’s Fiber in Metal Tubes (FIMTs) offer a pivotal solution for manufacturers of subsea cables, providing a blend of durability and advanced technology crucial for deep-sea environments. Our FIMTs are engineered to withstand the unique challenges of subsea applications, including high pressure, corrosive saltwater, and physical stressors.

The tubes are capable of housing up to 192 fibers, optimizing data transmission capacity in a compact form, essential for the confined spaces of subsea cables. Additionally, the availability of these components in continuous lengths of up to 50 kilometers reduces the necessity for frequent splicing, enhancing the overall integrity and reliability of the cable systems.

Backed by NBG’s commitment to excellence in manufacturing and quality control, our FIMTs are designed to be a vital component in the construction of robust, efficient subsea cable networks.

Our FIMT and fiber optic products for subsea cables are manufactured to customer specifications.

Below are just a few examples to demonstrate our production capabilities.

For subsea applications, NBG offers FIMTs in continuous lengths of up to 50 km. These extended lengths greatly reduce the need for splicing, enabling smoother and more efficient installations while enhancing overall system integrity by minimizing potential points of failure.

NBG’s FIMTs can accommodate up to 192 fibers with 200 µm coating in a single tube. This high fiber density maximizes data transmission capacity, making our solutions a cost-effective choice for large-scale subsea communication infrastructures.

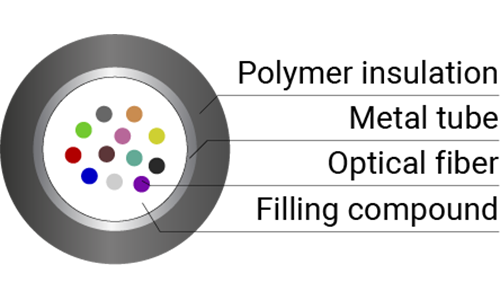

The size of the FIMT depends on the number and type of fibers. Our datasheets specify the minimum outer diameter for different fiber counts as well as the available wall thicknesses. The outer diameter can exceed the listed values and is fully customizable according to customer requirements.

NBG utilizes thixotropic gels with high hydrogen absorption capacity and high viscosity. The hydrogen absorbers prevent fiber darkening by capturing diffused hydrogen molecules, ensuring long-term signal integrity. With a filling degree exceeding 90%, the gel also provides the longitudinal water tightness required by subsea cable standards.

NBG collaborates with leading fiber suppliers worldwide to provide the fiber types and manufacturers requested by our customers. The maximum attenuation depends on both the fiber type and the fiber density. As a general guideline, attenuation within the FIMT is approximately 0.1 dB/km higher than the values specified in the raw fiber datasheets.

We’re here to help! Reach out to us for any technical inquiries or assistance.