We supply specialized Fiber in Metal Tubes (FIMTs) as core components for manufacturers of high and medium voltage cables. Our FIMTs are distinguished by their high fiber density, accommodating up to 192 fibers in a single tube—optimizing space and maximizing data transmission capacity.

Available in continuous lengths of up to 50 kilometers, our FIMTs minimize the need for splicing and enhance cable reliability. Every product reflects NBG’s commitment to precision manufacturing and strict quality control, ensuring seamless integration into advanced cable systems.

Our FIMT and fiber optic products for HV / MV cables are manufactured to customer specifications.

Below are just a few examples to demonstrate our production capabilities.

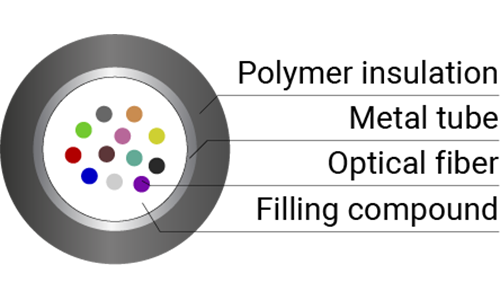

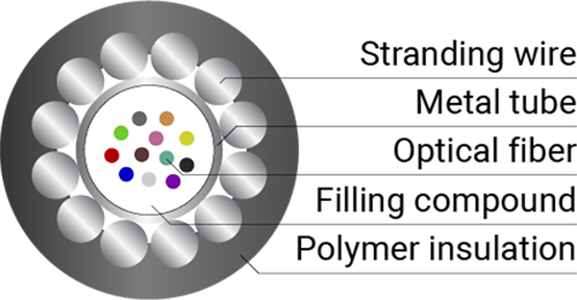

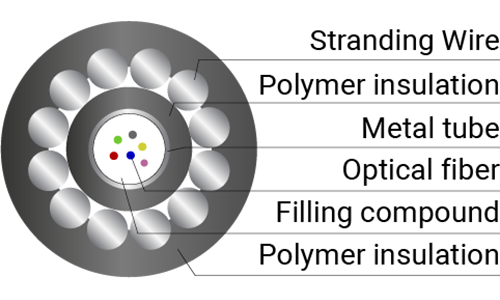

FIMTs are welded tubes, typically manufactured from stainless steel or nickel alloys, that encapsulate optical fibers within a thixotropic gel filling. This loose tube design shields the fibers from external physical and environmental influences, ensuring secure and reliable data transmission and sensing—particularly in high- and medium-voltage cable applications.

FIMTs enhance the functionality of electrical cables by enabling integrated data transmission and real-time monitoring through Raman, Brillouin, Rayleigh, or FBG-based sensing technologies.

Customers can choose from a wide range of steel and polymer grades, sizes, fiber counts, and fiber types. The FIMT design is determined by the overall cable construction and the intended purpose of the optical fibers. While fiber count and type define the minimum FIMT size, additional layers are added according to the cable design. Share your cable specifications or end-customer requirements with us, and we will develop the appropriate FIMT solution.

FIMTs provide superior mechanical protection for optical fibers through high crush resistance and exceptional breaking strength. These properties allow seamless integration into larger cable assemblies without the need for strain relief or additional armoring layers. FIMTs can also be supplied on customer machine drums for direct mounting on the stranding line.

FIMTs can be integrated into the cable structure as the central element or in between the conductors in trifoil configurations, or within the shield and armoring layers. Their position is determined by the intended function of the fibers and the overall cable design.

Distributed Fiber Optic Sensing (DFOS) is the ideal solution for monitoring and surveillance of modern HV and MV cables. Key benefits include fully distributed measurement points, immunity to electromagnetic interference (EMI), long-distance sensing, and no power requirement at the sensing location. Common applications include real-time thermal rating (RTTR), failure point detection, monitoring of land excavation or offshore anchoring/fishing activities, and cable load measurement through strain sensing.

We are collaborating with companies developing the next generation of superconductors and are ready to support your project as well.

We’re here to help! Reach out to us for any technical inquiries or assistance.